Forte, the new frontier of filter makers

Following years of research and technological improvement, Molins is glad to present the new version of Forte. The latest generation of single rod Filter Maker platform is able to produce up to 5,000 fpm.

The machine is based on the strong and reliable Molins technology combined with great flexibility and versatility. Introduction of fast size change features allows getting final length change in less than 1 hour and pass from KS to SS in less than 4 hours, maximising machine uptime.

Moreover, with a strong impact on machine versatility, application of capsule insertion, flavour applicator and NWA unit will be implemented.

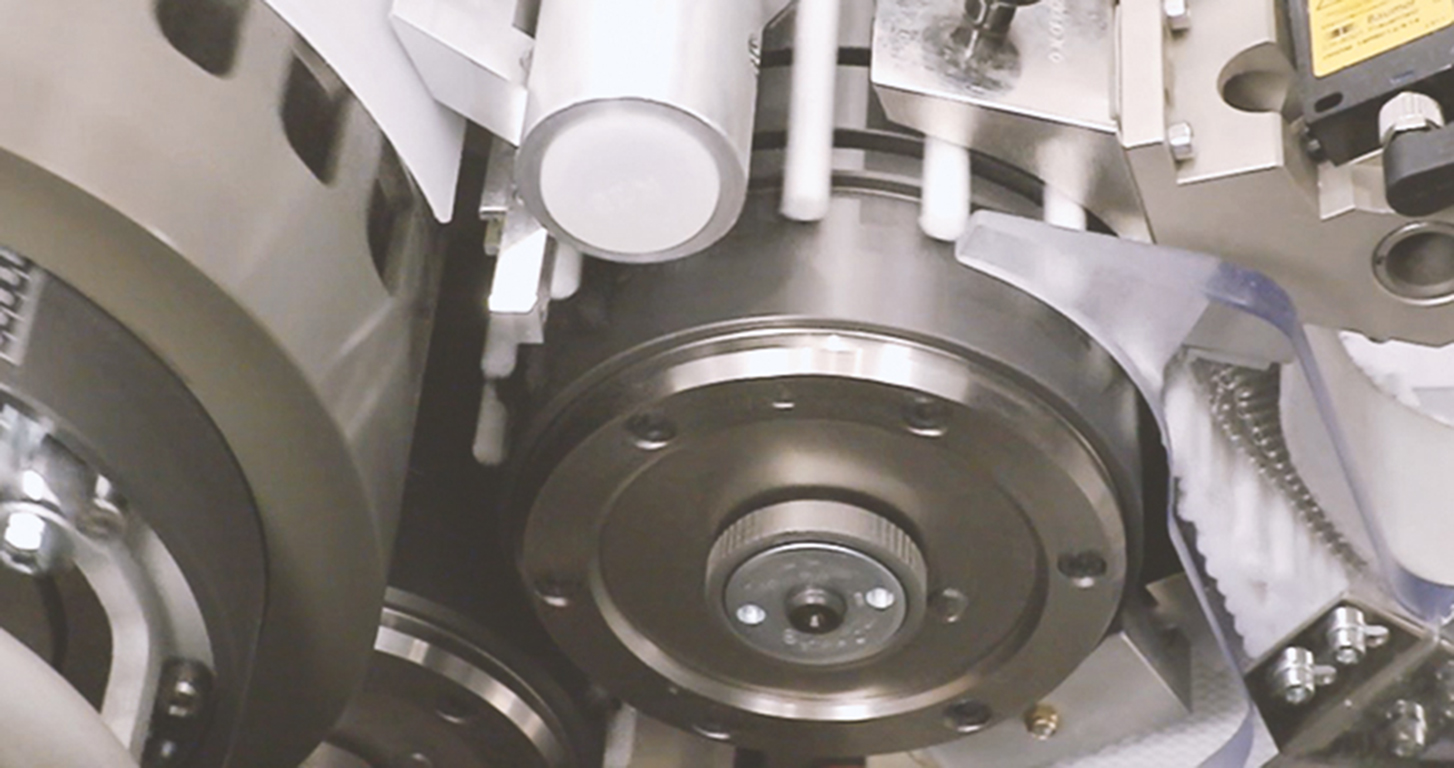

With a very compact layout, Forte is designed with a tow path at 1300 mm height and forming garniture at 1160 mm to ease any intervention and allow high process visibility, coupled with improved safety features applied through improved guarding.

Standardisation of key assembly groups throughout the Molins family of machines ensures reliable, cross platform functionality.

Focusing on that the new Forte has been developed with Paper splice unit, Bobbin turnover unit, Paper tension control and Cut-Off head as the main area of commonality with the Octave, ensuring tried and tested technology throughout.

Closed loop with Cerulean Quantum Neo could be a benefit in terms of reliable and consistent quality checks.

The Closed loop is the new system based on the automatic feedback from the off-line measuring station (Cerulean) to the main machine control (PLC) to achieve:

• Automatic product quality monitoring and reporting

• Automatic adjustment of machine setting

• Automatic calibration of the online sensors

Thanks to the above advantages, the new version of Forte represents the turning point in the manufacture of acetate filter rods, with the ability to guarantee reliability, versatility and economic savings to all Molins customers.